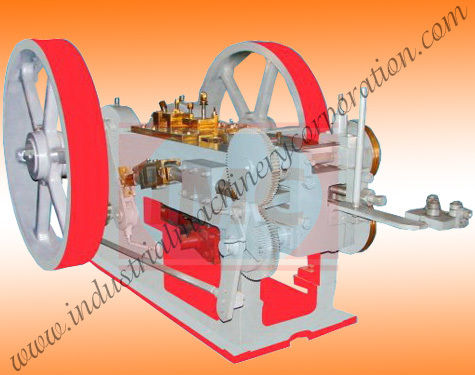

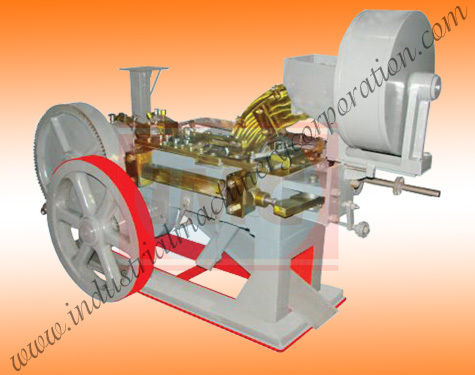

Automatic Cold Heading Machine

Product Details:

Product Description

We offer best available variants of Automatic Cold Heading Machine that are famed and demanded for their high-volume production. This line of Automatic Cold Heading Machine we design and offer is extremely durable and is made employing best grade raw material. Besides, being fabricated using advanced technology, these machines are also maintenance free and feature extended functional life.

Advantages:

- The Cut-off and knock-out mechanism in these machines have various safety devices. Thus, even during irregular functioning, the machine remains safe and hazard free.

- The Cold heading machine slide comes fitted with a mobile design that features two heading punches. These punches facilitate the processes of straightening & finishing.

- The two punches & dies can be easily regulated and adjusted at the accessible points and their operations can be directed manually.

The machines we offer have the vertical wire straightening bearing rollers designer equipment. This equipment is well designed and leads to straight wire feeding that further facilitates the processing of long bolt.

Only the best available grade steel that is heat-treated and grounded is utilized for making parts and components like rollers, roller pins, cames, etc., of these machines.

It Aids In Producing:

- Bolts

- Screws

- Rivets

- Taper Roller Heading, etc.

Cold Heading Machine Specifications:

| Model No. | Capacity (Length x Dia) | Production (Per Minute) | Power Required (H.P x RPM |

| IMC-CHM-2 | 2 x 1/4 (50MM x 6MM) | 80-85 | 3 x 960 |

| IMC-CHM-2.5 | 2.5 x 5/16 (65MM x 8MM) | 70-75 | 5 x 960 |

| IMC-CHM-3 | 3 x 3/8 (75MM x 10MM) | 60-65 | 10 x 960 |

| IMC-CHM-4 | 4 x 1/2 (100MM x 12MM) | 45-50 | 15 x 960 |

| IMC-CHM-5 | 5 x 5/8 (125MM x 15MM) | 35-40 | 20 x 960 |

| IMC-CHM-6 | 6 x 3/4 (150MM x 20MM) | 25-30 | 35 x 1440 |

Other Products in 'Bolt Making Machines' category

GST : 03BXNPS2799K1ZN

|

INDUSTRIAL MACHINERY CORP.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |