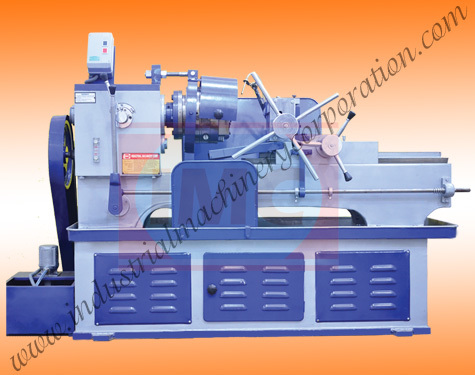

बà¥à¤²à¥à¤ थà¥à¤°à¥à¤¡à¤¿à¤à¤ मशà¥à¤¨

बà¥à¤²à¥à¤ थà¥à¤°à¥à¤¡à¤¿à¤à¤ मशà¥à¤¨ Specification

- ड्राइव

- Gearbox drive

- उत्पादन क्षमता

- 150 bolts/hour

- कंट्रोल सिस्टम

- फ़्रेम टाइप

- Rigid steel frame

- शोर का स्तर

- <75 dB

- परिचालन तापमान

- 5°C to 45°C

- फ़्रिक्वेंसी

- 50 Hz

- कनेक्टिविटी के विकल्प

- Single phase power

- कूलिंग सिस्टम

- Integrated water cooling

- पावर रेटिंग

- 1.5 kW

- सटीकता

- ±0.02 mm

- मशीन का प्रकार

- Threading Machine

- मोटर पावर

- 2 HP

- लुब्रिकेटिंग सिस्टम

- Automatic oil lubrication

- प्रॉडक्ट टाइप

- टेक्नोलॉजी

- पावर सोर्स

- पावर

- 2 HP

- प्रेशर

- Standard atmospheric

- सतह का उपचार

- आयाम (एल* डब्ल्यू* एच)

- 900 mm x 650 mm x 1200 mm

- वजन (किग्रा)

- 350

- रंग

- Blue & Silver

- उपयोग/अनुप्रयोग

- Threading of bolts, rods and fasteners

बà¥à¤²à¥à¤ थà¥à¤°à¥à¤¡à¤¿à¤à¤ मशà¥à¤¨ Trade Information

- Minimum Order Quantity

- 10 Units

- आपूर्ति की क्षमता

- 10 प्रति महीने

- डिलीवरी का समय

- 30 दिन

- मुख्य निर्यात बाजार

- एशिया

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About बà¥à¤²à¥à¤ थà¥à¤°à¥à¤¡à¤¿à¤à¤ मशà¥à¤¨

- Base

- Bed or Pillar Type Clamping Vice

- Die-Head

- Head Stock

- Saddle

Threading Machine Specification:

Precision Threading for Diverse Applications

Designed with advanced thread rolling technology, this machine reliably produces threads adhering to both metric and imperial standards. Its adjustable clamping system and variable speed allow for seamless adaptation to different bolt sizes and types, making it a versatile asset in industrial environments.

Durable Construction and Enhanced Safety

Built with a rigid steel frame and protected by a painted surface, the threading machine withstands demanding operations. Safety features like the emergency stop switch and enclosed design ensure operator protection. Alloy steel rollers and HSS dies maintain consistent threading quality during extensive use.

Efficient Operation and Low Maintenance

This machine is structured for convenient and efficient use, requiring just one operator. Integrated water cooling and automatic oil lubrication minimize maintenance needs while maintaining peak performance. Its high production rate supports large-volume threading operations with minimal downtime.

FAQs of Bolt Threading Machines:

Q: How does the bolt threading machine ensure precise thread formation?

A: The machine utilizes high-speed steel (HSS) dies, adjustable vise clamping, and thread rolling technology to achieve consistent and precise threads, maintaining an accuracy of 0.02 mm.Q: What types and sizes of bolts can I use with this machine?

A: You can thread bolts with diameters up to 25 mm and minimum lengths of 50 mm. It supports both metric and imperial threading standards, allowing for broad application.Q: When should I use the emergency stop switch?

A: The emergency stop switch should be activated immediately if any unsafe condition arises or when maintenance is required to ensure operator safety and protect the machine.Q: Where is this machine typically installed and used?

A: It is commonly installed in industrial workshops, manufacturing units, and fastener production facilities across India. Its compact dimensions allow flexible placement within workspaces.Q: What is the threading process on this machine?

A: The operator secures the workpiece in the adjustable vise, sets the required spindle speed using the control system, and initiates threading. Automatic lubrication and water cooling operate throughout for optimal results.Q: How is the threading machine powered and controlled?

A: The machine operates on electric power, compatible with both single and three-phase supply. It is controlled through a manual lever and an electrical start system for ease of use.Q: What are the main benefits of using this bolt threading machine?

A: Key benefits include high threading precision, efficient single-operator workflow, quick thread production (up to 150 bolts/hour), robust safety measures, low operational noise, and reduced maintenance due to automated systems.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in थ्रेडिंग मशीनें Category

रीबर थ्रेडिंग मशीन

फ़्रिक्वेंसी : 50 Hz

कूलिंग सिस्टम : Integrated Water Cooling

विशेषताएँ : Heavy duty body, Easy operation, High threading accuracy

मशीन का प्रकार : Rebar Threading

शोर का स्तर : ≤75 dB

उपयोग/अनुप्रयोग : Construction, Rebar Threading

स्कैफोल्डिंग पाइप थ्रेडिंग मशीन

फ़्रिक्वेंसी : 50/6 Hetrz (Hz)

कूलिंग सिस्टम : Air Cooling

विशेषताएँ : Heavy Duty

मशीन का प्रकार : pipe threading machine

शोर का स्तर : low db

उपयोग/अनुप्रयोग : Industrial

पोर्टेबल पाइप और बोल्ट थ्रेडिंग मशीन

फ़्रिक्वेंसी : 50/6 Hetrz (Hz)

कूलिंग सिस्टम : Air Cooling

विशेषताएँ : Heavy Duty

मशीन का प्रकार : bolt threading machine

शोर का स्तर : low db

उपयोग/अनुप्रयोग : Industrial

रॉड थ्रेडिंग मशीन

फ़्रिक्वेंसी : 50/6 Hetrz (Hz)

कूलिंग सिस्टम : Air Cooling

विशेषताएँ : Heavy Duty

मशीन का प्रकार : threading machines

शोर का स्तर : low db

उपयोग/अनुप्रयोग : Industrial

GST : 03BXNPS2799K1ZN

|

INDUSTRIAL MACHINERY CORP.

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें