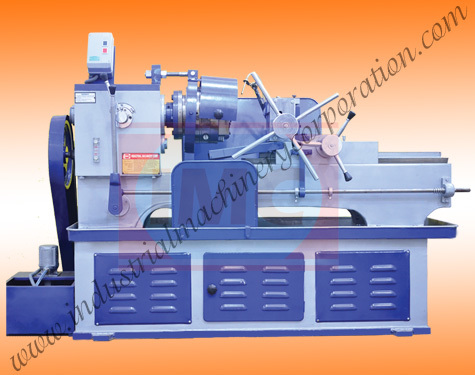

Scaffolding Pipe Threading Machines

Product Details:

Product Description

With the help of our competent professionals and state-of-the-art infrastructure facilities, we pertain to manufacturing, supplying and exporting Pipe Thread Cutting Machine. Having a thread capacity up-to 650mm, our machine is used for threading different plastic pipes with utmost perfection. Widely recommended for longer threads, this machine comes in different models and specifications. Offered Pipe Thread Cutting Machine is acknowledged for high efficiency, rigid body construction, longer service life, low maintenance and trouble-free operations.

Other details:

Scaffolding Pipe Thread Cutting Machine makes use of a one-of-a-kind of cutter called Tangential chaser for cutting the external threads. Die head rotates while the components remain still during the thread cutting process. The types of thread that can be cut using this machine can be categorized into taper and parallel, and sub-categorized into ACME, UNF, METRIC, BSPT, BSW, BSP, NPT, UNC, BSF Threads. The main components of Scaffolding pipe thread cutting machine, include the following:

- Base

- Saddle

- Head Stock

- Die Head

- Bed or Pillar Type Clamping Vice

THREAD CUTTING MACHINES are designed in a way to provide reliable performance and efficiency under every possible conditions with requirement of minimum maintenance. This model combines all fundamental of precise threading. Case hardened steel is employed for making all the gears with extra large face and tooth thickness. These gears cut on hobbing machine for noiseless operation at all speeds. The Scaffolding pipe threading machine is built with highest quality material and workmanship standards, that are closely integrated in COMPANY TRADITION.

DESIGN & WORKMANSHIP: The thread cutting machines offered by Industrial Machinery Corporation produce quality threads within their intended tolerance.

HEAD STOCK: A heavy duty geared Head Box of quality casting gives the necessary support to the spindle bearings. The gear type box is lubricated and fitted with three more heavy duty bearings.

THE BED: The pillar type bed has two steel made pillars that are finished & duly hard chrome plated in the hard chrome plating unit.

THE SADDLE: On the two pillars of the bed, the Saddle is precisely fitted. The saddle easily and accurately runs on pillars to the Head Stock alignment.

The APRON: The saddle is moved by the apron, with head transfer together with pillars through steel rack and pinion arrangements. Steel is used for making all the gears.

VICE JAWS: The alloy steel made vice jaws are fitted on the saddle and aligned with the head stock center fitted in a vice that is of a heavy duty box type. Heat treatment is carried out on the jaws. Screw on the saddle controls the jaw movements. Customers can get a range of IMC Scaffolding Thread Cutting Machines and Die Heads. 1/2" to 2.1/2" do/-

Specifications of Scaffolding Pipe Thread Cutting Machine

| Model | 1/2" to 2.1/2" (Pillar Type) |

| Saddle Movement | Upto 27" |

| Spindle Speed Range | 54-85 |

| Number of Spindle Speed | 2 |

| Threading Capacity | 1/2" to 2.1/2" |

| Production per Hour | 25-30 |

| H.P. Required | 7.5 H.P. 960 RPM |

| Lead Screw | Provided |

| Weight (KG) Aprox. | 1200 |

Other Products in 'Threading Machines' category

GST : 03BXNPS2799K1ZN

|

INDUSTRIAL MACHINERY CORP.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |